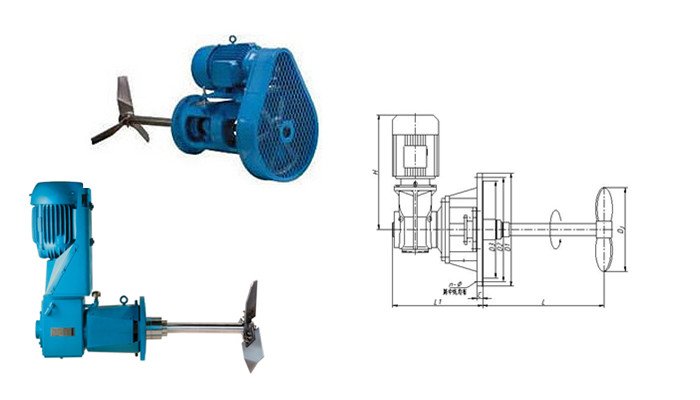

Agitator-Side Entry Agitator

Agitators-Side entry agitator

Description of side entry agitators

Side entry agitator has the advantages such as compact structure, high efficiency, stable transmission, low noise and easy disassembly. the stirring device is installed on the side wall of cylinder or tank equipment. Usually adopted axial flow impeller. CD’s side entry agitators are widely used in petrochemical, chemical, pharmaceutical, mineral, water treatment, pulp, coating, paint, paper, Flue Gas Desulfurization and so on.

Side entry agitator is a new type of mixer device, we can replace or repair seal or gear box without emptying the fluid in the tank. Equipped with a spiral type impeller , can get the highest mixing effect. in the case of equal power consumption.

For side entry agitator, the mixing device was installed on the side wall of tank, the impeller is usually used axial flow pattern, the type of TXL impeller was used more. in the same power consumption, can get the highest mixing effect, power consumption is only 1/3 ~ 2/3 of top entry agitator, the cost is only 1/4 ~ 1/3 of top entry agitator. Speed can catch 200 ~ 750r/min.

- Need to install the sealing device, generally use of mechanical seals.

- the stirring device is installed on the side wall of cylinder or tank equipment,

- Transmission shaft with special structure design, can easily replace the mechanical seals and bearing in the case of non disassembly of the whole machine

- high mechanical efficiency, compact structure, stable operation

- Flue Gas Desulfurization

- petrochemical,

- pharmaceutical

- Biofuels and bio refineries

- Hydrometallurgy

- water and wastewater

- mineral